Services

Laser cutting

up to 1” mild steel, aluminum, copper, nickel, stainless steel

CNC Automated laser cutting

large scale production jobs

Press brake

forming up to 3/8”

MIG, TIG, Spot welding

of steel, aluminum, stainless steel

Powder coating and painting

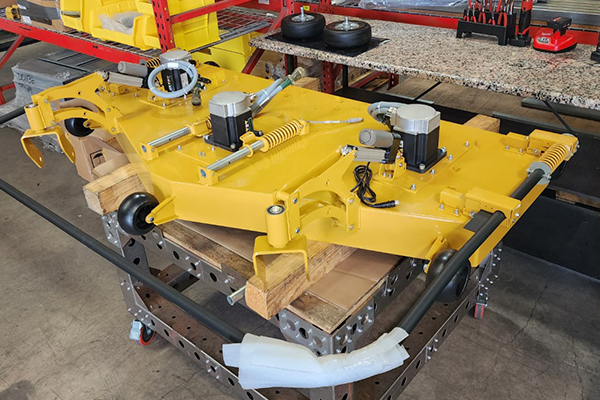

Complete Assembly

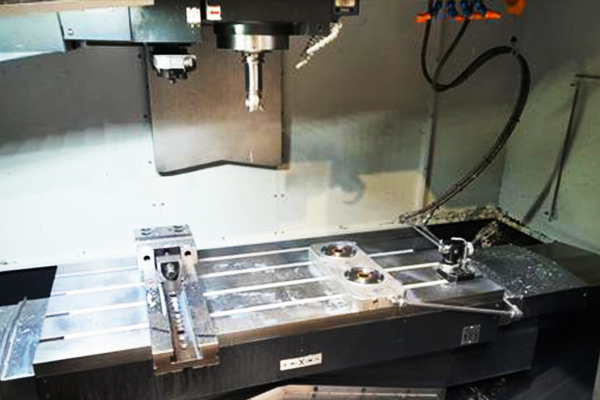

CNC Milling (3-Axis)

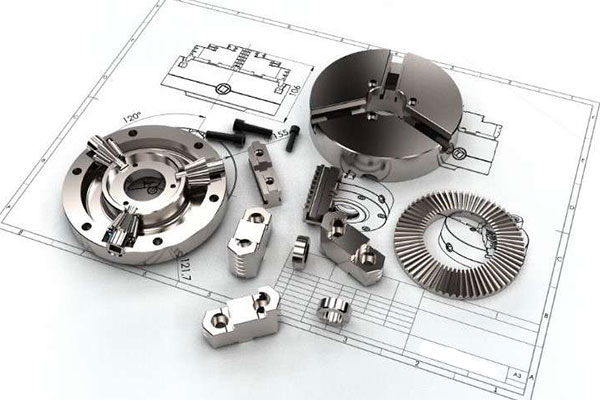

Design and Prototype

full time engineering on-site

Quality control

Shipping/delivery

Why Choose Aero Precision

Manufacturing Inc.?

Aero Precision Manufacturing Inc. creates partnerships designed to increase productivity and reduce total costs for its customers. Our team of professionals delivers standard and customized products at a competitive price that impacts the bottom line. Additional advantages of partnering with us include but are not limited to:

Innovative and cost-effective solutions designed to increase productivity and save time and money.

The highest quality staff in the industry. Streamlined processes designed to provide expertise and short lead times.

Laser cutting is a technology used in industrial manufacturing that uses a laser to vaporize materials, resulting in a cut edge.

Laser Cutting is the process of employing a laser beam to vaporize a material. Computer Numerical Control (CNC) Laser Cutting generally uses optics, an assist gas, and a guidance system to focus the laser beam into the workpiece.

Welding is the process of joining two pieces of material together with comparable melting points and composites using fusion.

Metal Inert Gas (MIG) welding is primarily used for large and thick materials. It uses a consumable wire that acts as both the electrode and the filler material. It is much after than TOG welding which leads to shorter lead times and lower production costs.

Tungsten Inert Gas (TIG) welding is primarily used for pipeline and pipe welding. Many industries such as aviation, aerospace, and sheet metal industries that work with thin materials and special materials such as titanium.

Powder-coating is a process used to create a hard finish that is tougher than conventional paint, powder coating is applied electrostatically and is then cured under heat to allow it to flow and form a "skin". The powder may be a thermoplastic or a thermoset polymer.

Aluminum, stainless steel, mild steel, galvanized steel, electroplated steel, and steel alloys

Ready to Get Started?

Have an idea or project in mind? Call us or schedule an appointment today!